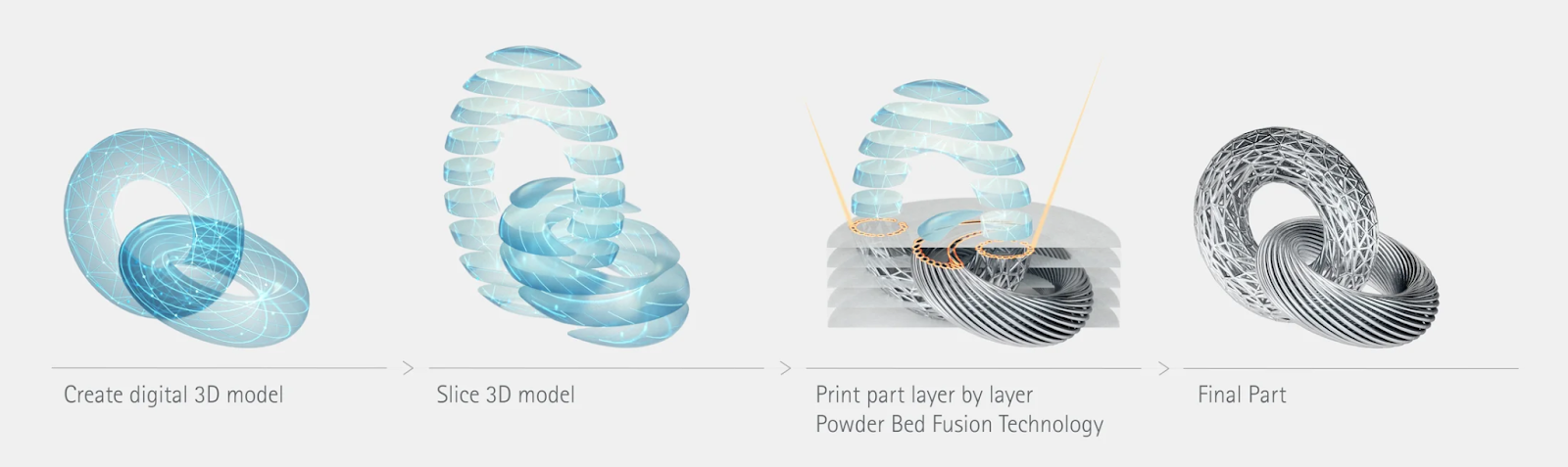

A thin layer of Powder (material) is added layer by layer onto a build platform in a controlled chamber. Then a powerful laser or lasers will melt the powder at the precise path or point specified by the computer from the fed CAD data. Later, the build platform is lowered and another layer of the powder is Added on top. Again the powder is melted and fuses with the below layer at the specific points. This process is repeated until the part is completed.

This technology was invented in the mid 1990’s but EOS developed this technology to perfection with the process and the materials.